14 Ways IoT is Impacting the Food & Agriculture Industry

The Internet of Things refers to smart devices that are capable of transferring information on a network. Although Kevin Ashton, the acclaimed co-founder, and director of the MIT Auto ID Centre, is credited with inventing the term, it wasn’t until 2008 – 2009 that the concept became widely known.

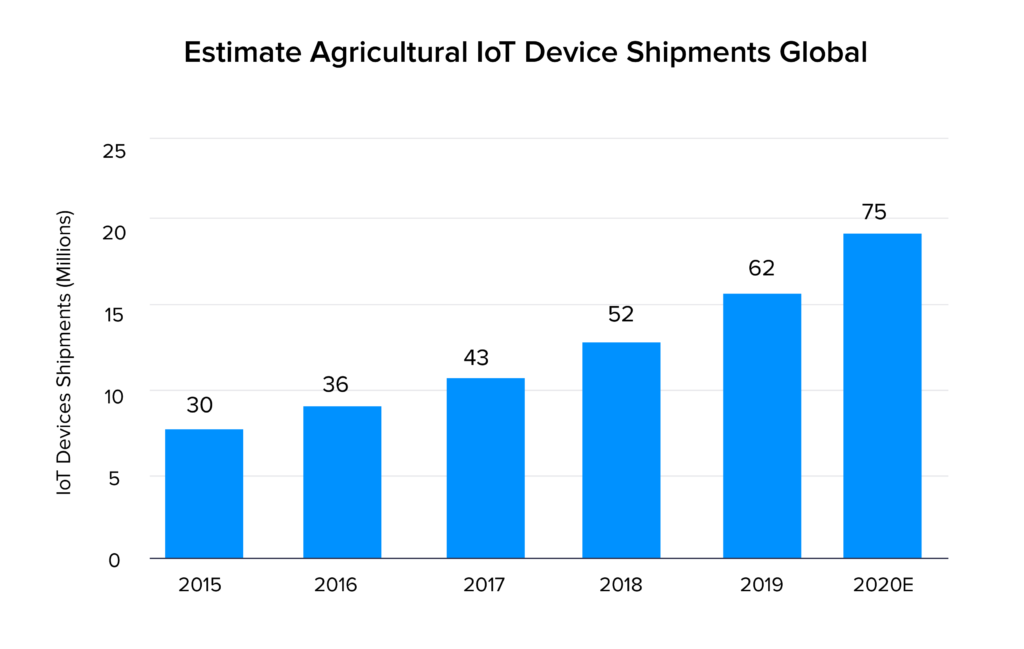

As internet-enabled devices multiplied in production and installations, there were 12.5 billion internet-connected devices in 2010, so did the general awareness associated with IoT. Fast forward to 2020, there are about 31 billion IoT devices amongst us and a considerably few questions around what is IoT. Today there are numerous IoT technologies that are still emerging and making its way to the industries.

As the IoT technology proliferates the marketplace, so does its form and utilities being realized by people in general. And why not? Combined with robotics and AI, the IoT technology hammers out human-dependencies from supply chains and reduces the cost to businesses. Nowhere is this more applicable than perhaps the food industry.

Beginning from the very farm that your food grows in, to the warehouses that store it and the retailers that distribute it, the food service industry has stepped in a new age of remote monitoring, sensing, and action that will have profound, and mostly positive, implications for its supply chain players. Let us find out how.

Applications of IoT in Agriculture

From disease control measures to cattle and field monitoring systems, IoT is making the project successful by transforming the industry of agriculture by putting the power back where it belongs. Into the farmers’ hands. Major sectors where this tech has found a solid footing are indoor farming, livestock management, and aquaculture among others. But how is IoT overcoming challenges and breaking new ground in farming?

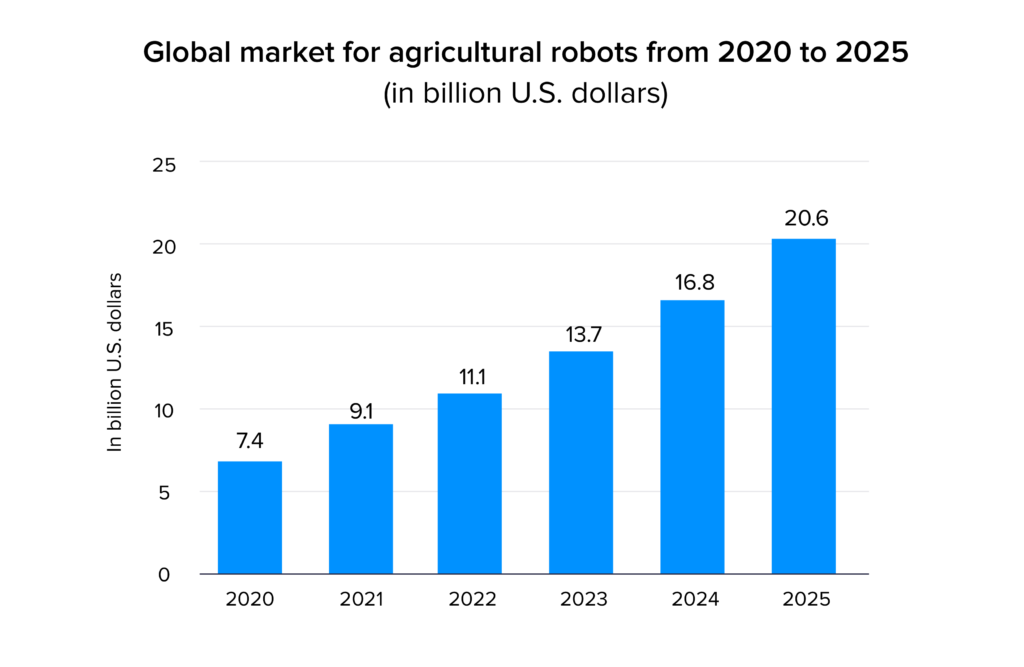

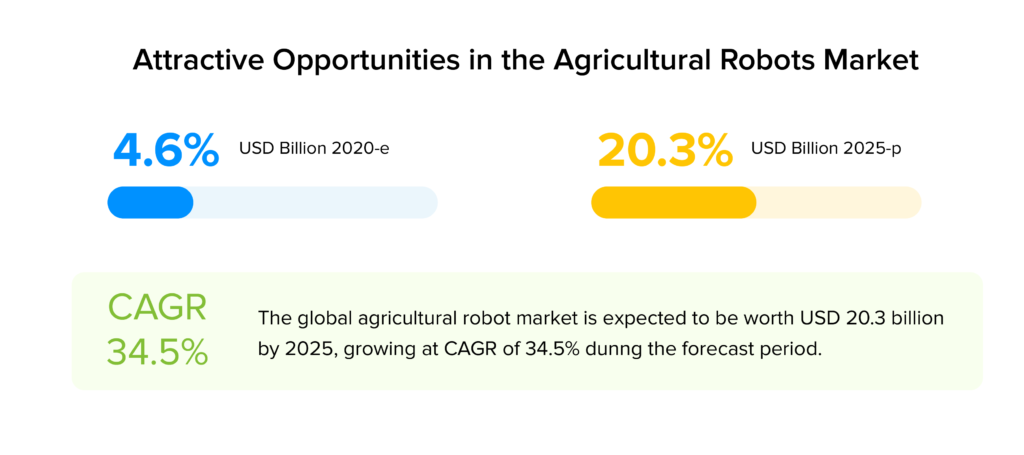

1. Robotics

Robots have come a long way since the third industrial revolution, abetted by the development of the internet. Although far from changing the face of the F&B industry, agricultural robots aka agribots could offer a circumventing solution to the problem of labor shortages. Unmanned Aerial Vehicles (UAVs) can be deployed to detect and exterminate weeds from the field. They could save farmers time, human resources, and spray volumes by acting precisely as per the demand. This saving translates into a healthy soil that has a lesser amount of pesticides/weedicides to absorb and more positive bacteria to preserve.

2. On-field Navigation

Machine learning, GPS, and the internet of things are making manned machine navigation a thing of the past. Farmers can remotely control their tractors, rotavators, and a host of agricultural machinery with a smartphone. As the code memorizes rough patches, it learns to alter gears and smoothen navigation to both protect the crops and the equipment.

3. Automated Crop Harvesting

Crop harvesting often turns out to be the plight of farmers often due to untimely harvests. Factors influencing such events could be the weather, untrained personnel, or other poor farm management. Harvesting robots could be trained with the wealth of information that we now possess to pick the right fruit at the right time. With the Internet of Things technology, farmers could grow high-value crops at scale than hedge their bets with varieties supported by minimum support prices.

4. Remote Sensing

Another way by which the food industry is scaling its appetite for the Internet of Things is by installing on-field sensors. By design, sensors are engineered to detect discrepancies in weather conditions, crop nutrition, soil pH, and more. Such a smartly coded crop monitoring system offers advance intel to farmers and warns them to prepare for exigencies.

5. Drones

Drones are yet another example of IoT in the food industry. The self-guiding technology makes use of GPS, image processing, infrared cameras, and ground control systems. New generation farmers are leveraging Drones-as-a-Service (DaaS) to predict crop yields, diagnose pest infestation, precision fertigation, and field supervision. Aerobotics is one of the few food tech startups that have made their mark in the field, literally. It combines drone scouting and multi-sensor analysis to predict crop health for longevity.

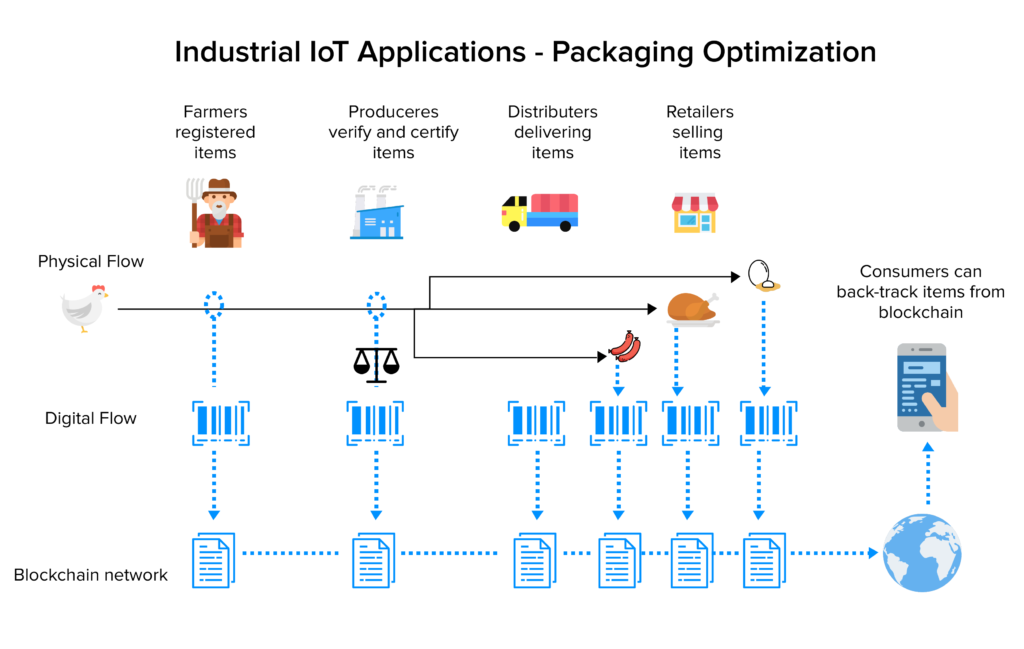

IoT in Food Packaging

The food manufacturing industry is high on the deployment of the Industrial Internet of Things (IIoT). The two most suited application areas of IoT that have emerged so far are manufacturing and packaging. Both the SMBs and enterprise vendors have realized the value-added, multifold benefits of IoT in the F&B industry and the following sections illustrate further on it.

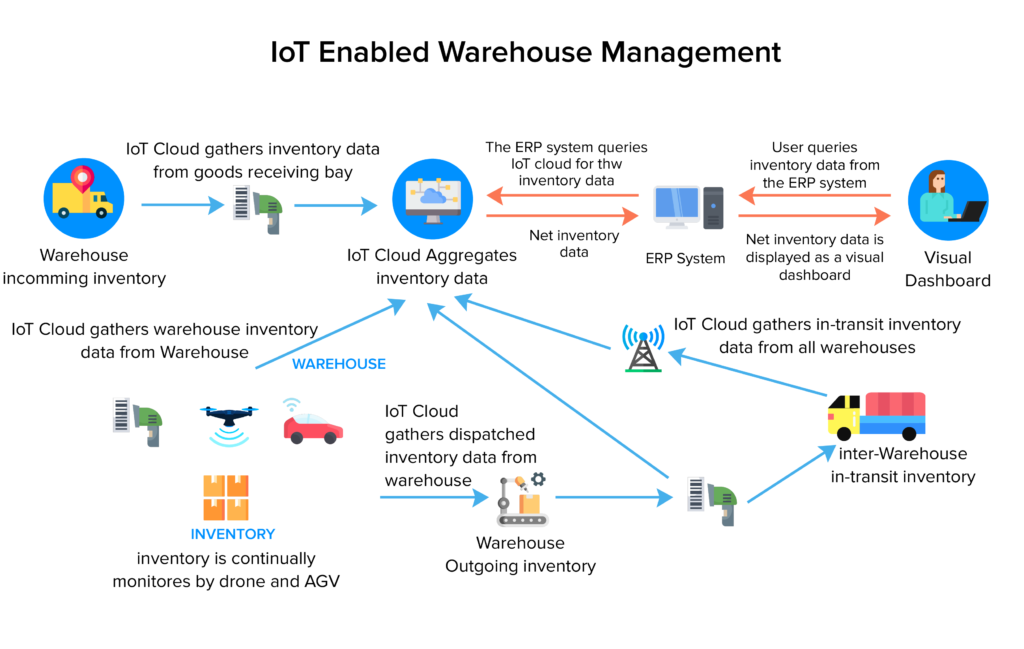

6. Warehouse Management

The use of IoT in warehouse management is known to be a recurrent top IoT trend. Inventory tracking consumes a lot of overheads and unaccounted muscle-power in the food service industry. Massive swathes of data need constant reconciliation and therefore must be accurate. Sensors act as immaculate tracking devices for warehouse inventory, the data pertaining to which is updated in the software real-time. Consequently, the stock loading times are optimized, managers maintain a magnified vigil on supply chains, due to which the storage space is fully taken advantage of.

7. Vision Picking

Automated guided vehicles (AGVs) and collaborative robots can go so far in fetching deeply buried stocks in densely packed shelf lines. So if human intervention can’t be uprooted it can surely be made smart and that is what vision picking glasses do. Think Google glass with a lot more information packed in it. Vision picking marries the internet of things with the food industry helping humans identify the right storage zones.

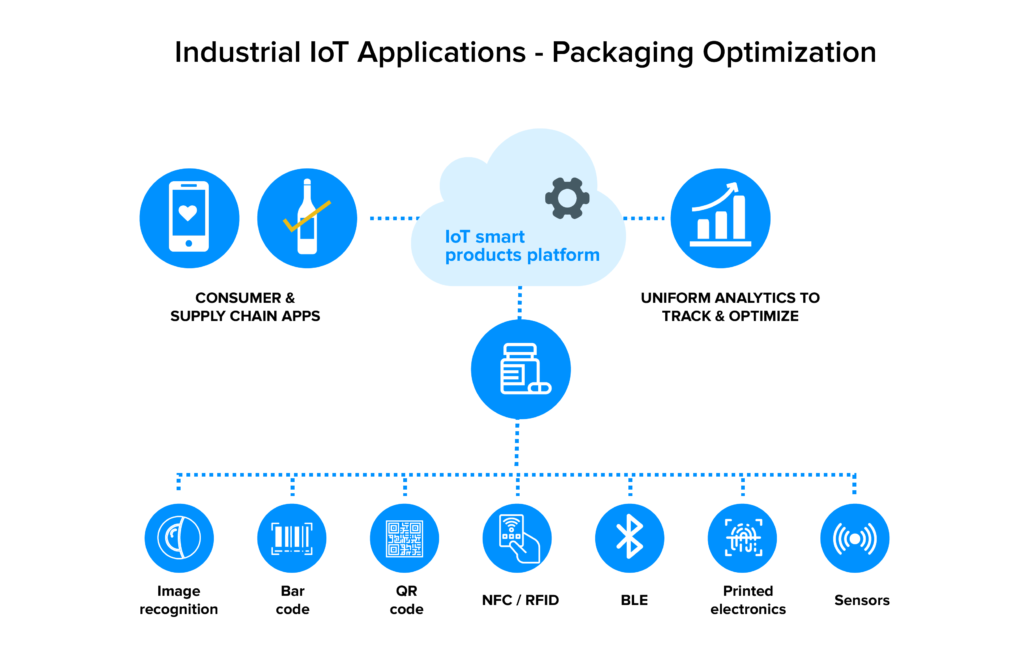

8. Product Authenticity Labels

Internet-enabled microchips can be embedded in state-of-the-art food packaging that will expose the originality of the product, once scanned. QR codes are spin-offs of the same concept that evaporate doubts over the authenticity of the product. Especially in times like COVID, customers ordering food online are terrified than ever about the origins of its supply chain. As a result of which an IoT app development company like us is working seriously to offer this feature to our clients.

9. Smart Sensors

You never know what customers demand, at least that is what our experience as a food delivery app developer tells us. Integrating QR codes isn’t enough. They come in telling us that their stock keeping units are packages with such advanced sensors that indicate not just the veracity of quality but whether the sealing has been broken or not, the source of its ingredients, yadda yadda yadda. For the uninitiated, that is yet another way the internet of things technology is transforming the industry of food.

10. Digital Triggers

Modern-day customers love exploring the possibilities associated with food. While sharing the supply chain credentials established trust, offering insights on how to unleash and savor lesser-known recipes takes engagement to impressive levels. As a food app development company, we recommend IoT triggers that inform viewers of add-on combinations to enjoy edible items with. It’s a strategic way to augment food packaging with dynamic, ever-changing information that cannot be printed in the first place.

11. Flash Sale Coupons

One of the IoT challenges a food delivery app development company like us comes across on our daily roaster is how to make products fly off the shelf without any marketing gimmicks. Turns out we can use IoT (duh!) to run flash-sales for items with low shelf life or those closing in on expiry. Buy one get two offers makes most of us drool.

IoT in Food Retail

While open food markets and retailers are the two major platforms for distributing farm produce to consumers, restaurants, road-side eateries, and hotels act as other outlets. Due to this reason, restaurant mobile app developers have been reshifting focus on how to drive IoT in operations. Let’s see how businesses can go about their business the smart way with IoT.

12. Reverse Vending Machines

For locations that regulate strict recycling legislations, reverse vending machines are a common sight. They incentivize people to deposit disposable/recyclable materials such as cans and plastic bottles by paying them a certain sum. Integrating IoT-enabled programs notifies the retail staff to empty the machine before a queue begins to form. Lesser queues translate into happy customers the lifetime effect of which can be felt in return-customers and their purchase orders.

13. Remotely Controlled Storage Units

Refrigeration or storage is a huge concern for the food manufacturing industry. At most locations, operations still depend on the same old, fractured system of human aided supervision. This discounts the fact that the human eye is prone to judgemental errors not to mention the public holidays when the storage units could be under-staffed. IoT-enabled remote monitoring systems can play a cameo in filling such ubiquitous gaps. They can prompt supervisors to action if the temperatures are fluctuating beyond the requisite limits and save precious food. Restaurant app development services like us, can create handheld smart controllers with which the user could moderate temperatures without physical presence.

14. In-store Energy Management

Temperatures inside large supermarkets, malls, and retail chains are usually regulated by HVAC systems. But they are not intelligent and lack the ability to alter air-conditioning/central heating. An all-encompassing IoT suite could stabilize room temperature in accordance with the outside world. This would help in preserving perishable consumables that cannot bear the brunt of frequent temperature change. In addition, this energy optimization would even save millions of dollars in utility bills contributing further to cost efficiency.

Key Takeaway

The Internet of Things will continue to expand its applications territory into the foreseeable future to varied industries the foremost of which shall remain F&B. Given the well-established line of achievements Appinventiv has won in the years since inception, IoT solutions are definitely up our alley. Let’s put it this way, if we don’t excite you with our elevator pitch when we meet, the drinks on us. We’ll be waiting for your call.

strategies your digital product..